24 Apr 2019

About Our Client:

Organic molecules have become increasingly important in the last few decades in the development of high-tech electronics. These include organic light-emitting diodes (OLEDs) for flat screen display technology such as TVs. computers and mobile devices.

Organics are also used as key components in light-harvesting devices for solar cells and as organic field effect transistors (OFETs) for microelectronics. The Rawson Group research focuses on the fundamental interplay between molecular synthesis, solid state structure and physical properties with a particular interest in magnetic, conducting and optical properties of the molecules they prepare.

The Rawson group approach is centered around the synthesis and reactivity patterns of group 15/16 heterocycles, particularly those containing the elements N, P, S, and Se and the generation of stable free radicals. They exploit crystal engineering approaches to understand and design molecule-based materials and use a range of in-house techniques for compound characterization including:

and reactivity patterns of group 15/16 heterocycles, particularly those containing the elements N, P, S, and Se and the generation of stable free radicals. They exploit crystal engineering approaches to understand and design molecule-based materials and use a range of in-house techniques for compound characterization including:

* NMR and EPR spectroscopies,

* UV/vis and fluorescence measurements,

* Single crystal and powder X-ray diffraction,

* DSC and TGA

* Computational studies (DFT).

Measurements of magnetic and conducting properties are undertaken through collaborations with internationally leading experts in the field. “The Rawson Group – making designer radicals for materials science.”

About Our Project:

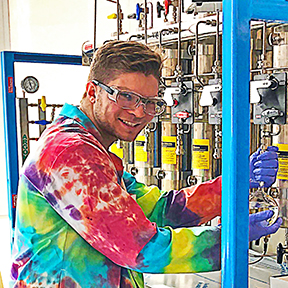

To assist in their research goals PPT engineered, constructed, tested, delivered, and commissioned a six solvent purification system. A partial listing of the advantages and quality components consisted of:

Caltech / The Peter’s Group at t...

16 May 2019

The University of Rochester, Che...

14 May 2019

The Jeremy Rawson Group, at the ...

24 Apr 2019

New SPS for The University of Te...

11 Apr 2019

Rose Research Group, Department ...

08 Mar 2019

Solvent Systems – Harris Researc...

25 Feb 2019

Solvent Purification System – Da...

25 Feb 2019

Install and Training for 2 Five ...

25 Feb 2019

25 Feb 2019

Custom 6 column one solvent puri...

25 Feb 2019